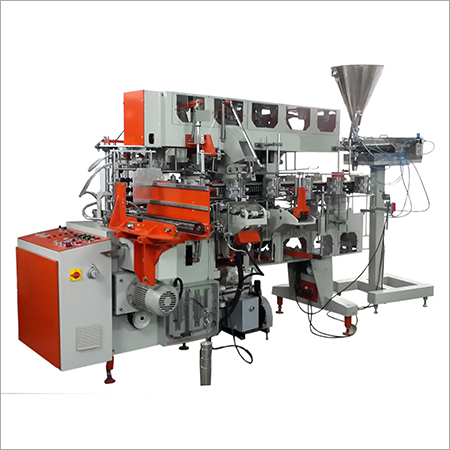

Semi Pneumatic with Servo Auger Filler Machine

Product Details:

- Power Supply Electric

- Filling Range 10 gm to 1000 gm (with suitable parts)

- Usage Filling and packaging of powder products

- Features Accurate filling, Easy operation, Hygienic design, Low maintenance

- Noise Level Low

- Application Powder filling in pouches/sachets Spices, Milk Powder, Coffee, Flour, Pharmaceuticals, Chemicals

- Type Semi Pneumatic with Servo Auger Filler Machine

- Click to View more

Semi Pneumatic with Servo Auger Filler Machine Price And Quantity

- 1 Unit

Semi Pneumatic with Servo Auger Filler Machine Product Specifications

- Semi Pneumatic with Servo Auger Filler Machine

- Electric

- 2200 mm x 1200 mm x 2400 mm

- Silver/Grey

- Accurate filling, Easy operation, Hygienic design, Low maintenance

- Filling and packaging of powder products

- Electric

- 30-60 Pouches/Min (Depending on product and pouch size)

- 10 gm to 1000 gm (with suitable parts)

- 2.5 kW

- 420 kg (Approx.)

- Stainless Steel (SS304 Contact parts)

- Low

- 220V/50Hz, Single Phase

- PLC Based Control Panel

- Powder filling in pouches/sachets Spices, Milk Powder, Coffee, Flour, Pharmaceuticals, Chemicals

- Servo Motor driven auger, Durable body, Quick size change-over

- Yes

- Center/Three Side/ Four Side (Customizable)

- Filling Machine

- Semi Automatic

Semi Pneumatic with Servo Auger Filler Machine Trade Information

- Per Month

- Week

- Telangana, Andhra Pradesh, South India, Karnataka, Kerala, Tamil Nadu

Product Description

Semi Pneumatic with Servo Auger Filler Machine

Technical Specifications:

| Sealing Types | Centre Sealing / Three Side Sealing |

| Packing Speed | 30-60 pouches / Minute (Depending upon the size) |

| Packing Material | Any Heat Sealable Laminated Film |

| Motor | 1 HP, 220V DC, Three Phase |

| Power Consumption | 3 KW |

| Pouch Width | Min 50mm, Max 190mm |

| Pouch Height | Min 60mm, Max 300mm |

| Reel Width | 185mm |

| Power Requirement | 2KW, Single Phase, 220/VAC |

| Range of Packing Capacity | 25 GM TO 500 GM |

| Feeding System | Clutch Brake / Servo Auger |

| Optional attachment (At on Extra Cost) | Electronic Batch Coding Device / Hot Ribbon Coding System / Solid Ink Roller Coding System / End Pouch Conveyor Nitrogen Flushing System |

| Applications | Semi Pneumatic with Auger Filler to pack all types of Spice Powder (Turmeric/ Coriander/Chilly/ Sambar/ Rasam) |

| All type of Masala Powder (Mutton Masala/ Chicken Masala/ Kabab Powder/ Garam Masala etc.,) | |

| Flour Items (Rice/ Wheat/ Maida/ Basin/ Ragi) and all type of free flow powders |

Precision Filling for Consistent Results

Boasting a servo motor-controlled auger, this machine ensures highly accurate dosing of powdered products, maintaining a filling accuracy of 1%, dependent on the products consistency. The system automatically adjusts for varying pouch sizes and weights, making it suitable for a range of applications in the food, pharmaceutical, and chemical industries.

Flexible and User-Friendly Operation

Equipped with a touchscreen HMI and PLC-based control system, the machine allows for quick and intuitive adjustments. Tool-less changeover facilitates fast switching between different products or pouch sizes, streamlining production for manufacturers handling various powders.

Built for Safety and Hygiene

Stainless steel contact parts ensure product hygiene, while features like emergency stop switches, overload protection, and interlocked doors provide operational safety. Easy dismantling of the auger assembly further supports thorough, effortless cleaning, maintaining high sanitary standards.

FAQs of Semi Pneumatic with Servo Auger Filler Machine:

Q: How does the servo auger filler machine ensure high filling accuracy?

A: The machine utilizes a servo motor to control the auger, providing precise and consistent movements that deliver an impressive filling accuracy of 1%, depending on the consistency of the product being handled.Q: What packaging materials can be used with this machine?

A: It supports a variety of heat-sealable laminated films, including PET/PE, paper/aluminum foil, offering flexibility for different pouch styles such as center, three-side, or four-side sealing.Q: When is tool-less changeover beneficial in the production process?

A: Tool-less changeover allows operators to quickly switch between products or pouch sizes without the need for specialized tools, minimizing downtime during cleaning or product transitions.Q: Where is this filling machine typically used?

A: This equipment is ideal for manufacturing facilities in the food, pharmaceutical, and chemical sectors across India, especially for powder filling applications involving spices, milk powder, coffee, flour, and more.Q: What is the process for cleaning and maintaining the auger assembly?

A: The auger assembly is designed for easy dismantling without tools, streamlining cleaning and maintenance and ensuring hygiene as required in sensitive industries.Q: How does the machine enhance operator safety during use?

A: Safety features include an emergency stop switch, overload protection, and interlocked doors, providing comprehensive safeguards for operators throughout machine operation.Q: What are the main benefits of using this semi pneumatic filling machine?

A: Key advantages include precise dosage control, rapid and easy size changeover, hygienic construction, low maintenance requirements, and high-speed packagingmaking it a practical choice for efficient and safe powder product packaging.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Packing Machines' category

|

E. C. MACHINES INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese