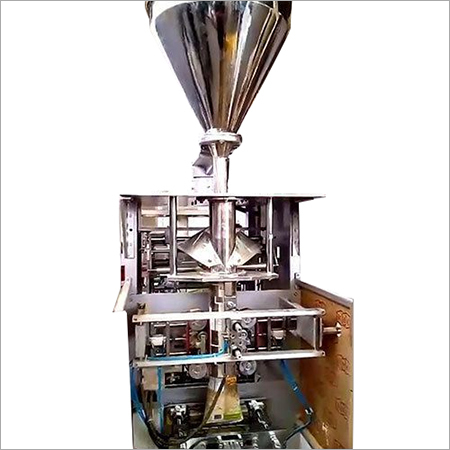

Collar Type wtih Multi Head Weigh Filler Machine

Product Details:

- Noise Level 78 dB

- Filling Range 10g 2000g (Depends on Product/Configuration)

- Power Supply AC

- Usage Industrial Food Packaging

- Features Servo Motor Draw Down, Photocell Registration, Automatic Film Tracking

- Application Granules, Snacks, Dry Fruits, Seeds, Confectionery, Cereals, Frozen Foods, etc.

- Type Collar Type With Multi Head Weigh Filler Machine

- Click to View more

Collar Type wtih Multi Head Weigh Filler Machine Price And Quantity

- 1 Unit

Collar Type wtih Multi Head Weigh Filler Machine Product Specifications

- 220V/380V, 50/60Hz (Customizable)

- Granules, Snacks, Dry Fruits, Seeds, Confectionery, Cereals, Frozen Foods, etc.

- PLC Control Panel with Touch Screen (HMI)

- Stainless Steel

- Weigh Filler

- 78 dB

- Electric

- 10g 2000g (Depends on Product/Configuration)

- 30-70 Pouches per minute (varies with product and pouch size)

- Yes

- Automatic

- Industrial Food Packaging

- 1700 mm x 1100 mm x 2600 mm (varies by model)

- Servo Motor Draw Down, Photocell Registration, Automatic Film Tracking

- Collar Type With Multi Head Weigh Filler Machine

- High-Speed Accurate Weighing, Easy Changeover, Low Maintenance

- Silver / Metallic Grey

- 2.5 kW 4.5 kW (Depending on Model)

- Center Sealed / Three-Side or Four-Side Sealed

- Approx. 850-1200 kg

- AC

Collar Type wtih Multi Head Weigh Filler Machine Trade Information

- 20 Unit Per Month

- 2-3 Week

- South India, Tamil Nadu, Karnataka, Andhra Pradesh, Telangana, Kerala

Product Description

Collar Type wtih Multi Head Weigh Filler Machine

TECHNICAL SPECIFICATIONS

| Packing Material | Heat-sealable Laminated Film |

| Sealing Type | Centre Sealed pouch: Pillow type with fin seal on backside and cross seals at top and bottom of pouch |

| Filling System | 10 head multi combination weighing system. |

| Packing Speed | 50 to 60-packets/ minute. |

| Max reel width | 580mm |

| Max reel diameter | 450mm |

| Nos. of Reels | 1 - (Side Panel Front Side Panel) |

| Film draw mechanism | Lenze make Clutch-Brake |

| Film Control in unwind system | Motorized Mechanical Web Edge Controller |

| P.L.C. | Delta |

| A.C. Drive | Delta |

| Temperature Controller | PID Based |

| Photocell | ISO Standard |

| Product Contact Parts | AISI SS-316 |

| Construction Parts | PU Coated MS |

| Safety | Totally enclosed by Polycarbonate Doors |

| Filling accuracy | 0.1gm to 1gm. |

| Registration on Film (Photo mark) | YES |

| Electrical Supply & Requirement: | 3 x 220 VAC +/- 10% 10KW Please specify your power supply condition |

| Control Voltage | 220 VAC |

| Compressed Air Supply | 8 cfm @ 6 Bar |

| Pneumatic Cylinders | Festo / Janatics / SMC |

| Machine Dimension: | 2000mm x 1350mm x 3200mm (L x W x H) |

| Machine Weight: | 1800Kg approx. |

High-Speed and Versatile Packaging Efficiency

This machine combines rapid operation (3070 pouches per minute) with highly accurate weighing and sealing, accommodating various bag types and sizes. Designed with robust stainless steel construction and advanced PLC control, it meets rigorous industrial demands while offering customizable film widths up to 420 mm. The combination of multihead weighing with collar-type packaging ensures excellent repeatability and flexibility.

User-Friendly, Automated, and Safe Operation

Equipped with a 7-inch color touch screen and a multi-language interface, the machine simplifies operation for diverse users. Automated processes include servo motor draw down, photocell registration, film tracking, and optional date coding. Safety is enhanced through emergency stop, interlock, and overload protection features, promoting a secure workspace and seamless production flow.

FAQs of Collar Type wtih Multi Head Weigh Filler Machine:

Q: How does the collar type with multi head weigh filler machine improve packaging efficiency?

A: The machine integrates a 10 or 14 head multihead weigher with a collar type former, enabling fast and consistent weighing and filling of products. This setup can handle 3070 pouches per minute, reducing downtime and delivering precise product quantities, which minimizes product waste and optimizes throughput.Q: What types of bags and materials are compatible with this packaging machine?

A: It supports pillow, gusseted, and flat pouch bags using various film materials such as laminated film, PE, OPP, and PET, with adjustable film widths up to 420 mm and thicknesses between 0.040.09 mm. The system accommodates different sealing types, including center, three-side, or four-side seals.Q: When is cleaning or maintenance required, and how is it performed?

A: Routine cleaning is simplified with tool-free hopper removal, making maintenance fast and convenient. It is recommended to clean the machine after each production cycle and during changeovers to uphold hygiene standards, especially in food processing environments.Q: Where can this machine be used effectively?

A: The machine is ideal for industrial food packaging environments, such as snack processing plants, dry fruit manufacturers, cereal packing units, confectionery factories, and frozen food suppliers. Its versatility and high-speed output suit both large-scale and medium-scale packaging operations.Q: What is the process of operation for this packaging machine?

A: Product is dispensed through the multihead weigher into a forming tube, where bags are formed, filled, and sealed automatically. The control system manages film tracking, servo motor movements, and pouch sealing, which are monitored via the 7-inch color touch screen. Optional features like date coding and photocell registration enhance accuracy and traceability.Q: How does the machine benefit industrial food manufacturers?

A: Industrial users gain enhanced productivity, consistent product quality, and flexibility to package a range of food products. The machines accuracy reduces giveaway, its speed improves output, and its easy-to-clean design minimizes downtime, ensuring a hygienic and efficient operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Packing Machines' category

|

E. C. MACHINES INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese