Liner Carton Packing Machine

Product Details:

- Features Corrosion Resistant, Durable, Easy Maintenance

- Usage Suitable for Bulk Packaging

- Noise Level Low

- Application Carton Packaging in Food, Pharma, FMCG Industries

- Power Supply Single/Three phase

- Filling Range As per carton size

- Type Liner Carton Packing Machine

- Click to View more

Liner Carton Packing Machine Price And Quantity

- 1 , , Piece

- 95000.00 - 145000.00 INR

Liner Carton Packing Machine Product Specifications

- 1200 kg

- Automatic

- Carton Packaging in Food, Pharma, FMCG Industries

- Single/Three phase

- High Efficiency, User-friendly Operations

- Liner Carton Packing Machine

- 3-5 kW

- 220-240 V

- Blue & White

- Yes

- 3200 x 1450 x 1750 mm

- As per carton size

- 1200-1500 cartons/hour

- Carton Sealer

- Top & Bottom Flap Sealing

- PLC Based

- Low

- Suitable for Bulk Packaging

- Electric

- Mild Steel

- Corrosion Resistant, Durable, Easy Maintenance

Liner Carton Packing Machine Trade Information

- 1 , , Piece Per Month

- 1 Months

- Karnataka, Tamil Nadu, Andhra Pradesh, Kerala, South India, Telangana

Product Description

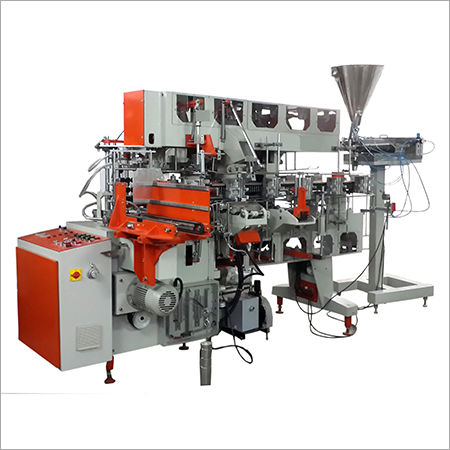

Liner Carton Packing Machine

Technical Specifications:

|

Output |

Minimum 22 To Maximum 25 Carton Per Minute. |

|

Carton Outfeed |

Height To Carton Base: 500mm Approx. |

|

No. Of Stations |

14 Station |

|

Dosing System |

Manual Feeding |

|

Product Contact Parts |

Ss |

|

Other Parts |

M.S Coated, C.I & Ss |

|

Electrical Motors |

Hindustan / Crompton |

|

Electrical Components |

Standard Grade |

|

Size Change |

All Carton Dimensions Can Be Changed Within Given Range |

|

Electric Supply |

Standard 440 / 220 Volt, 3 Phase |

|

Power Consumption |

4-5 Kw, (depending On Equipment) |

|

Floor Space |

6 X 4.5 Meter (working Space) |

|

Machine Weight |

1200-1500 Kgs. Approx. |

|

Filling |

Filling Can Be Done Only At 1 Station. |

|

Compressed Air Requirement |

4 Cfm @ 4 Kg / Sq. Cm. |

|

Application |

Inner Pouch, All Out |

Efficient, Automated Carton Packing

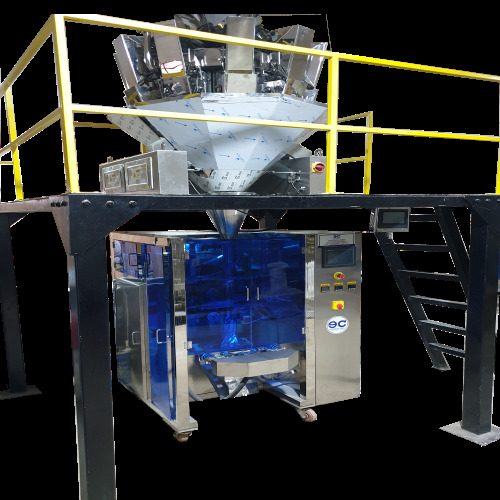

Boost productivity in your packaging line with a fully automatic, computerized carton packing machine featuring adaptive PLC control. The systems high-speed operation enables efficient handling of carton sizes ranging from 150 mm to 600 mm, with a capacity of up to 1500 cartons per hour. Its mild steel frame guarantees robust durability, while its smooth PVC conveyor ensures gentle carton transit.

Designed for Safety and Ease of Use

Operator safety is prioritized with integrated emergency stop buttons and interlock switching, reducing workplace risks. The user-friendly interface and centralized manual lubrication system make operations straightforward and keep maintenance requirements minimal. Whether sealing top or bottom flaps, this machine provides consistent results every time.

Versatile Applications Across Industries

Ideal for high-volume producers in the food, pharmaceutical, and FMCG industries, the Liner Carton Packing Machine automates your packaging process, ensuring reliable and consistent output. Its compatibility with various carton sizes and adjustable speed offers flexibility, while on-site installation and comprehensive support guarantee a smooth transition into your workflow.

FAQs of Liner Carton Packing Machine:

Q: How does the automatic carton feeding mode benefit production?

A: The automatic carton feeding mode streamlines the packing process by reducing manual intervention, ensuring consistent spacing and orientation of cartons for efficient, high-speed sealing and packing. This leads to smoother workflows and increased throughput.Q: What safety features are included in this carton packing machine?

A: Safety is ensured with integrated emergency stop buttons and interlock switching mechanisms. These features immediately halt operations in case of an emergency or improper access, protecting operators and equipment alike.Q: When is on-site installation recommended for this machine?

A: On-site installation is recommended for new users or complex operations to ensure proper setup, calibration, and integration into existing lines. This service is available across India and helps optimize performance from day one.Q: Where can this packing machine be effectively utilized?

A: This carton packing machine is suitable for bulk packaging needs in facilities dealing with food, pharmaceutical, or FMCG products. Its flexible handling of a wide range of carton sizes makes it ideal for diverse manufacturing environments.Q: What is the process for maintaining the centralized manual lubrication system?

A: Routine maintenance involves manually operating the centralized lubrication mechanism at specified intervals, ensuring all key moving parts remain properly lubricated for smooth, reliable performance and extended machine life.Q: How is the packing speed controlled and adjusted?

A: Packing speed can be easily adjusted through the PLC-based control system, allowing operators to adapt throughput rates as needed for different product runs or production targets without interrupting operations.Q: What are the main benefits of using this liner carton packing machine?

A: Key benefits include high packing efficiency (up to 1500 cartons/hour), low noise operation, compatibility with varying carton sizes, robust mild steel construction, user-friendly design, reduced operator requirement, and enhanced worker safety.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Packing Machines' category

|

E. C. MACHINES INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese