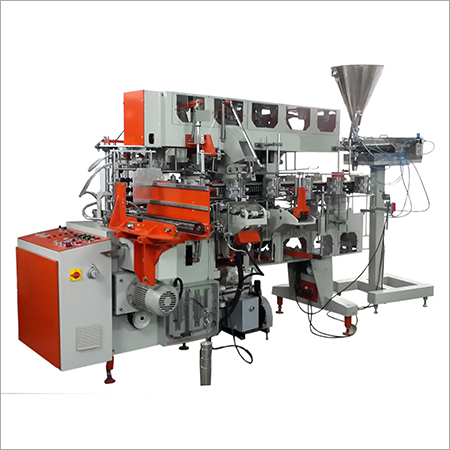

Automatic Chips Packing Machine

850000.0 INR/Piece

Product Details:

- Noise Level Low

- Application Snacks Packaging (Potato Chips, Namkeen, Kurkure, etc.)

- Filling Range 10-100 grams (customizable)

- Usage Industrial Snacks Food Packaging

- Features Touch Screen Panel, Error Indication, Stainless Steel Construction, Easy Operation

- Power Supply Three Phase

- Type Automatic Chips Packing Machine

- Click to View more

X

Automatic Chips Packing Machine Price And Quantity

- 1 Piece

- 850000.0 INR/Piece

Automatic Chips Packing Machine Product Specifications

- Electric

- 450 kg

- Snacks Packaging (Potato Chips, Namkeen, Kurkure, etc.)

- Touch Screen Panel, Error Indication, Stainless Steel Construction, Easy Operation

- Yes

- Three Phase

- Automatic

- Efficient, High Durability, Low Maintenance

- 1150 x 950 x 2000 mm

- Industrial Snacks Food Packaging

- Filling Machine

- Low

- 35-60 packs/min

- 3 kW

- 220-380 V

- Silver / Metallic Grey

- PLC Control

- 10-100 grams (customizable)

- Stainless Steel

- Heat Sealing

- Automatic Chips Packing Machine

Automatic Chips Packing Machine Trade Information

- 1 Piece Per Day

- 3 Days

Product Description

This electricity driven Automatic Chips Packing Machine uses PE, aluminum foil and PP as its packaging raw materials. Suitable for packing of potato chips, this equipment adopts back sealing technology to maintain standard quality of packed product. Advanced micro computer controlled technology of this machine ensures its fast operation. Stepper motor of this equipment manages bag length. Its PID temperature controller helps to maintain its ambient internal temperature. This packing machine is equipped with advanced pressure sensor of imported quality, hopper, food grade steel made bucket elevator and easy to clean working platform. Stainless steel exit conveyor of this machine promotes smooth discharge of packed products. We are a renowned trader and manufacturer of best grade Automatic Chips Packing Machine.

Technical Details

| Probability of Inaccuracy | +/-2% |

| Capacity (pouch per hour) | 1000-2000 |

| Machine Power | 1-2 HP |

| Automation Grade | Semi-Automatic |

| Voltage | 380V |

| Speed | 8-10 Pouches per minute |

Precision and Speed for Snack Packaging

This machine guarantees exact snack portioning with 1% packing accuracy and customizable filling (10100 grams). It can efficiently handle a variety of film materials, ensuring robust packaging for potato chips, namkeen, and similar snacks. Suitable for both medium and large-scale production settings.

User-Friendly Operation and Maintenance

With a PLC control system and LCD touch screen, operators can easily monitor, adjust, and troubleshoot the packing process. Error indications simplify maintenance, while the stainless steel construction enhances longevity and hygiene compliance in dry, dust-free environments.

Mobility and Versatile Application

Equipped with a wheeled base, this machine provides flexibility for positioning within the production space. Its automatic functions, adaptable bag sizes, and high-speed output make it suitable for various snack products and operational layouts.

FAQs of Automatic Chips Packing Machine:

Q: How does the Automatic Chips Packing Machine ensure consistent packing accuracy?

A: The machine utilizes advanced PLC control and precise weighing mechanisms to achieve a packing accuracy of approximately 1%, guaranteeing uniform pack sizes for every cycle.Q: What types of snacks and packaging films can this machine handle?

A: It is designed for packaging a wide range of snacks such as potato chips, namkeen, and kurkure. It accommodates laminated films, PET/PE, BOPP, and similar materials with a thickness of 0.040.09 mm.Q: When is routine maintenance required for optimal performance?

A: Routine maintenance is minimal due to the machines stainless steel build and robust design. However, regular cleaning and periodic checks after each shift or production batch are recommended to ensure continuous performance.Q: Where should the packing machine be installed for best operation?

A: For optimal function, the machine should be installed in a dry, dust-free area with an ambient temperature between 5C and 45C. Proper ventilation and a stable power source are necessary for smooth operation.Q: What is the process for adjusting bag size and filling range?

A: Both bag width and length are adjustable through the LCD touch screen interface, accommodating widths from 80 to 200 mm and lengths from 100 to 300 mm. The filling range can be set to fill packs from 10 to 100 grams, catering to various product requirements.Q: How does the mobility feature benefit snack manufacturers?

A: With its wheeled base, the machine can be easily repositioned within the production area. This flexibility supports dynamic factory layouts and can help streamline production flow as operational needs change.Q: What are the main benefits of using this chips packing machine?

A: This packing solution offers efficient high-speed packing, consistent sealing, user-friendly operation, and reliable construction. The result is reduced labor, minimal downtime, and consistent, high-quality packaging for a competitive edge.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Packing Machines' category

We are inviting local inquiries from Karnataka, Kerala, Andhra Pradesh, Tamil Nadu, Telangana, Borders of Orissa & Borders of Maharashtra.

|

E. C. MACHINES INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese