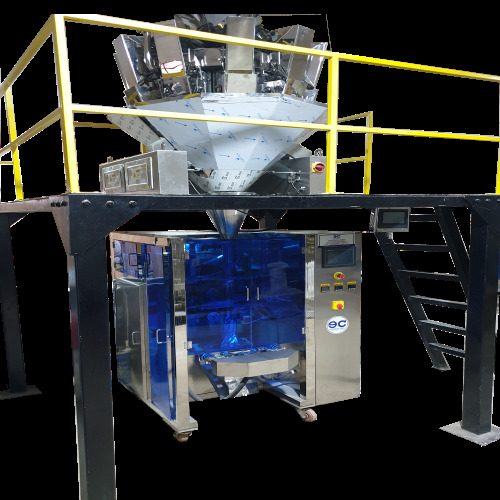

Collar Type With Servo Auger Filler Machine

Product Details:

- Power Supply Single/Three Phase 50-60 Hz

- Application Powder Packaging (Spices, Milk Powder, Coffee, Flour, Pharmaceuticals)

- Usage Packaging of Free Flow and Non-Free Flow Powders

- Noise Level Low

- Features Servo Controlled Auger, Adjustable Bag Length, Safety Sensors

- Filling Range 10 gm to 1000 gm

- Type Collar Type with Servo Auger Filler Machine

- Click to View more

Collar Type With Servo Auger Filler Machine Price And Quantity

- 1 Unit

Collar Type With Servo Auger Filler Machine Product Specifications

- Automatic

- Silver / Grey

- Center Seal / Pillow Pack

- 10 gm to 1000 gm

- Packaging of Free Flow and Non-Free Flow Powders

- Low

- 1200 mm x 900 mm x 2000 mm

- Auger Filler

- 2.5 kW

- Yes

- Collar Type with Servo Auger Filler Machine

- Servo Controlled Auger, Adjustable Bag Length, Safety Sensors

- High Accuracy Filling, Easy Changeover, Low Maintenance

- Stainless Steel

- Powder Packaging (Spices, Milk Powder, Coffee, Flour, Pharmaceuticals)

- 500 - 700 Kg

- PLC Based with Touch Screen HMI

- 220V / 380V, 50 Hz

- Single/Three Phase 50-60 Hz

- Servo Motor Driven

- 30-80 Pouches Per Minute (Depends on Product & Quantity)

Collar Type With Servo Auger Filler Machine Trade Information

- Per Month

- Week

- Kerala, Karnataka, Andhra Pradesh, South India, Tamil Nadu, Telangana

Product Description

Collar type with servo auger filler machine

Technical Specifications:

| Sealing Types | Centre Sealing |

| Packing Speed | 30-60 pouches / Minute (Depending upon the size) |

| Packing Material | Any Heat Sealable Laminated Film |

| Motor | 1 HP, 220V DC, Three Phase |

| Power Consumption | 3 KW |

| Pouch Width | Min 50mm, Max 190mm |

| Pouch Height | Min 60mm, Max 300mm |

| Reel Width | 185mm |

| Power Requirement | 2KW, Single Phase, 220/VAC |

| Range of Packing Capacity | 25 GM TO 1 KG |

| Feeding System | Auger Filler |

| Approx. Weigh of the Machine | 550 Kgs |

| Optional attachment (At on Extra Cost) | Electronic Batch Coding Device / Hot Ribbon Coding System / Solid Ink Roller Coding System |

| Applications | Collar Type with Auger Filler to pack all types of Spice Powder/ All type of Masala Powder/ Flour Items and all type of free flow powders |

High-Precision Packaging for Powders

Achieve consistent and reliable packaging results with the servo-controlled auger filler system. This machine ensures high accuracy in filling dosages for a broad range of powders, including spices, flour, pharmaceuticals, and more. Advanced controls and robust construction make it ideal for demanding production environments requiring quality and efficiency.

User-Friendly Operation and Easy Maintenance

Operators benefit from an intuitive PLC-based control system with a touch screen HMI, allowing straightforward adjustments and monitoring. The design enables quick changeovers in under 15 minutes, reducing downtime and optimizing productivity. Routine maintenance is simplified thanks to stainless steel construction and accessible components.

Versatile Packaging Options and Materials

Compatible with various heat-sealable laminated films like PET/PE and BOPP, this machine supports multiple pouch formats, including pillow and optional gusseted styles. Its flexible design allows businesses to package a variety of products with different bag lengths and shapes, catering to diverse market needs.

FAQs of Collar Type With Servo Auger Filler Machine:

Q: How does the automatic bag length adjustment work on this machine?

A: The bag length is adjusted automatically via the PLC-based control system. Operators can set the desired pouch length using the touch screen HMI, and servo-driven pulling ensures precise and consistent bag formation with minimal manual intervention.Q: What packaging materials are compatible with this machine?

A: This machine is designed for heat sealable laminated films such as PET/PE, BOPP, and similar materials, making it suitable for various demanding packaging applications in the food and pharmaceutical industries.Q: When is the auger filler system preferred over other filling methods?

A: The servo-controlled auger filler system is ideal for packaging both free-flow and non-free-flow powders, such as spices and milk powder, where high accuracy and dust-free delivery are important. It is especially beneficial for fine powders and cohesive materials that are challenging for other filling methods.Q: Where is the Collar Type With Servo Auger Filler Machine commonly used?

A: This machine is widely utilized in the food, chemical, and pharmaceutical industries, particularly for packaging powders into pillow or gusseted pouches in production facilities across India and abroad.Q: What is the changeover process and how long does it typically take?

A: Changeover involves swapping packaging film and adjusting the auger or forming collar to accommodate new pouch sizes. The design of the machine allows for a rapid changeover, typically taking less than 15 minutes, ensuring minimal production downtime.Q: How does the machine ensure operator safety during operation?

A: Safety is prioritized through integrated features such as emergency stop buttons, interlock mechanisms on guards, and overload protection, ensuring safe operation throughout the packaging process.Q: What are the main benefits of using this servo auger filler machine?

A: Key advantages include high filling accuracy, low maintenance needs, rapid changeovers, versatile pouch formats, compatibility with a wide range of powders, reliable safety features, and efficient synchronization between filling and packaging operations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

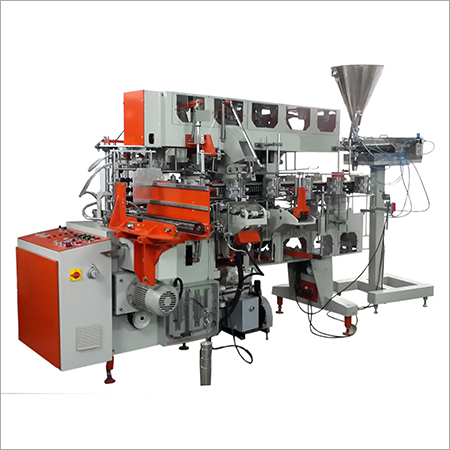

Other Products in 'Packing Machines' category

|

E. C. MACHINES INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese