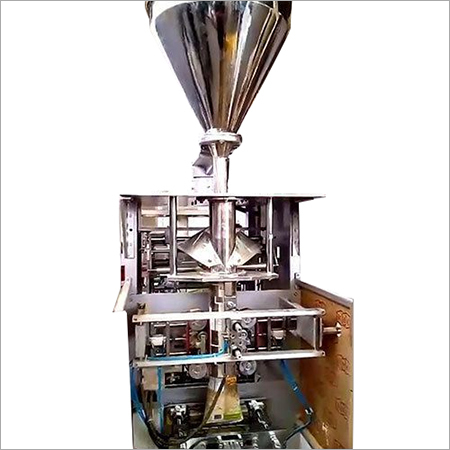

Semi Automatic Auger Filler

95000.00 - 145000.00 INR

Product Details:

- Features Hopper with Agitator, Quick Changeover, Adjustable Filling Speed

- Noise Level Low

- Filling Range 10 gm to 1000 gm

- Application Powder, Spices, Flour, Chemical, Pharmaceutical and Food Industries

- Usage Industrial Filling of Powder Products

- Power Supply Single Phase

- Type Semi Automatic Auger Filler

- Click to View more

X

Semi Automatic Auger Filler Price And Quantity

- 1 Unit

- 95000.00 - 145000.00 INR

Semi Automatic Auger Filler Product Specifications

- Easy to Operate, High Precision Filling, Durable Construction

- Digital Control Panel

- Electric Motor

- Low

- Silver

- Semi-Automatic

- Industrial Filling of Powder Products

- 10 gm to 1000 gm

- Single Phase

- Up to 25 bags/min

- 0.8 kW

- 220V / 50Hz

- Stainless Steel

- Hopper with Agitator, Quick Changeover, Adjustable Filling Speed

- No

- Powder, Spices, Flour, Chemical, Pharmaceutical and Food Industries

- Filling Machine

- 90

- Not Applicable (Filling Only)

- Semi Automatic Auger Filler

- 620 mm x 650 mm x 1800 mm

Semi Automatic Auger Filler Trade Information

- 20 Unit Per Month

- 2-3 Week

- Telangana, Karnataka, Tamil Nadu, Andhra Pradesh, South India, Kerala

Product Description

Semi Automatic Auger Filler

Machine fitted with:

- 2HP 3phase Motor 1440rpm

- Auger screw for powder feeding system

- Clutch and Brake system / Servo Motor

- SS hopper: Capacity 20 kg approx.

- Auto filling and manual mode with peddle switch

- Height adjustable pouch stand

- Contact parts made of SS 304 grade

High Precision and Versatile Application

This semi-automatic auger filler ensures high precision filling with an accuracy of 1%, making it suitable for a wide range of powders, spices, flour, chemicals, and pharmaceutical products. Its adjustable filling range from 10 grams to 1000 grams and compatibility with various packaging materials make it a versatile solution for industrial applications.

User-Friendly Operation and Maintenance

Equipped with an LCD digital control panel, manual height adjustment, and quick changeover features, the auger filler guarantees easy usability. Its low maintenance requirement, durable stainless steel construction, and hopper with agitator further enhance convenience for operators, reducing downtime and maximizing efficiency.

Safety and Durability Built In

The machine prioritizes operator safety with integrated overload protection and an emergency stop mechanism. Its mirror-polished, stainless-steel finish ensures longevity and hygiene while operating efficiently at low noise levels. Suitable for demanding environments, this auger filler is a reliable choice for continuous industrial use.

FAQs of Semi Automatic Auger Filler:

Q: How does the semi-automatic auger filler achieve high filling accuracy?

A: This auger filler utilizes precise screw dosing mechanisms, combined with a digital LCD display and variable dosage control, allowing for consistent and accurate filling with a deviation of only 1%. Its design is especially suitable for powders and fine granular materials.Q: What types of packaging materials can I use with this machine?

A: You can fill a variety of packaging formats including plastic bags, composite bags, bottles, and containers. The adaptability makes it suitable for goods destined for varied market requirements.Q: When should I perform maintenance on this auger filler?

A: Routine maintenance is minimal due to the machines robust construction. It is recommended to inspect and clean the hopper, auger, and contact surfaces after each shift or product changeover to ensure optimal performance and hygiene.Q: Where is this auger filler commonly used in industry?

A: This equipment finds wide application in pharmaceutical, chemical, food, and spice industries. Its versatility makes it ideal for production lines in factories requiring accurate and efficient powder filling.Q: What is the process for adjusting the fill level and speed?

A: Dosage control and filling speed are adjusted via the digital control panel, while manual height adjustment allows for flexibility with various container sizes. Quick changeovers facilitate smooth transitions between different product batches.Q: How does the machine ensure operator safety during use?

A: It incorporates overload protection and an emergency stop button, which promptly halts operations in case of a fault or hazard, safeguarding both the operator and the equipment.Q: What are the key benefits of using this semi-automatic auger filler?

A: Benefits include high filling precision, enhanced safety features, ease of operation, quick setup changes, low operating noise, and reliable performance with various powders across multiple industries.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Packing Machines' category

We are inviting local inquiries from Karnataka, Kerala, Andhra Pradesh, Tamil Nadu, Telangana, Borders of Orissa & Borders of Maharashtra.

|

E. C. MACHINES INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese