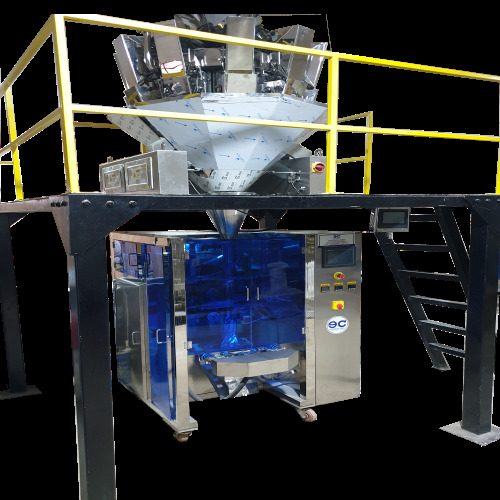

Semi Pneumatic Four Head Weigh Filler Machine

Product Details:

- Power Supply Single Phase

- Noise Level Low

- Application Filling granules, seeds, pulses, tea, spices, dry fruits, powders, and similar products

- Usage Food Packaging, Pharmaceutical, Chemical Industries

- Features Digital Weighing System, Easy Cleaning, Pneumatic Controlled

- Filling Range 10 gm to 1000 gm (Adjustable)

- Type Semi Pneumatic Four Head Weigh Filler Machine

- Click to View more

Semi Pneumatic Four Head Weigh Filler Machine Price And Quantity

- 1 Unit

Semi Pneumatic Four Head Weigh Filler Machine Product Specifications

- Food Packaging, Pharmaceutical, Chemical Industries

- Stainless Steel (SS 304 Grade)

- Filling granules, seeds, pulses, tea, spices, dry fruits, powders, and similar products

- Four Head Weighing, Fast Changeover, High Accuracy

- Compatible with vertical and horizontal sealers

- Low

- 10 gm to 1000 gm (Adjustable)

- Single Phase

- Approx. 350 Kg

- PLC Based

- Semi Pneumatic Four Head Weigh Filler Machine

- Metallic Silver

- 1500-1800 packs per hour (depending on product & pack size)

- Weigh Filler

- 1.5 kW

- Yes

- Semi-Automatic

- 2200 mm x 900 mm x 1750 mm approx.

- Electric

- 220 V Single Phase / 50 Hz

- Digital Weighing System, Easy Cleaning, Pneumatic Controlled

Semi Pneumatic Four Head Weigh Filler Machine Trade Information

- Per Month

- Week

- Yes

- South India

Product Description

Semi Pneumatic with Four Head Weigh Filler Machine

Technical Specifications:

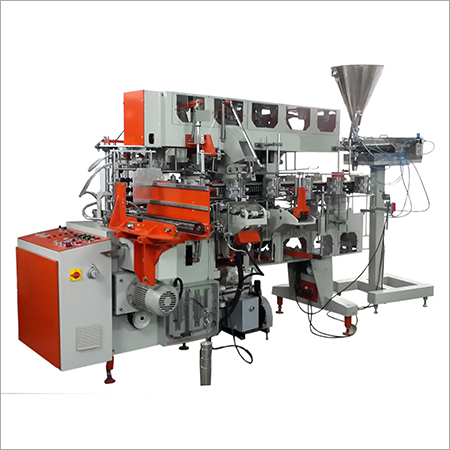

| Sealing Types | Centre Sealing / Three Side Sealing / Four Side Sealing |

| Packing Speed | 20-25 pouches / Minute (Depending upon the size of the product) |

| Packing Material | Any Heat Sealable Laminated Film |

| Motor | 1 HP, 220V DC, Three Phase |

| Power Consumption | 3 KW |

| Pouch Width | Min 50mm, Max 190mm |

| Pouch Height | Min 60mm, Max 300mm |

| Reel Width | 185mm |

| Power Requirement | 2KW, Single Phase, 220/VAC |

| Range of Packing Capacity | 25 GM TO 500 GM |

| Feeding System | Through Weighing System / End Pouch Conveyor |

| Approx. Weigh of the Machine | 600 Kgs |

| Optional attachment (At on Extra Cost) | Electronic Batch Coding Device / Hot Ribbon Coding System / Solid Ink Roller Coding System/Nitrogen Flushing |

| Applications | Semi Pneumatic with Weigh Filler to pack Whole Spices/ Pulses/ Rice/ Dry Fruits/ Masala Peanut/ Batani/ Namkeen/ Mixture / Tutti Fruity |

Accurate and Flexible Packaging Solutions

Our Semi Pneumatic Four Head Weigh Filler Machine offers precision-filled packaging with an accuracy of +/- 0.2%, suitable for diverse products and industries. The digital LCD display and PLC-based control system make operation intuitive, enabling fast changeovers for different bag sizes and product types. Its vibratory hopper ensures even product flow, supporting reliability and consistent filling performance.

Hygienic and Robust Construction

Designed with food-grade stainless steel (SS 304), this weigh filler suits food, pharmaceutical, and chemical applications. Contact parts are easy to access and clean without tools, minimizing downtime. The rigid frame with anti-vibration pads ensures stability, and its elegant polished and mat finish reflects its superior build quality.

Enhanced Safety and Seamless Integration

Safety is embedded with overload and jam protection, allowing continuous and safe operation. The machine can be effortlessly integrated with conveyors, sealing, and coding systems, optimizing your packaging line. Its mobility featuressuch as heavy-duty caster wheelsenable easy relocation for dynamic production environments.

FAQs of Semi Pneumatic Four Head Weigh Filler Machine:

Q: How does the Semi Pneumatic Four Head Weigh Filler Machine maintain high filling accuracy?

A: This machine utilizes four digital weighing heads and a vibratory hopper to deliver consistent, precise fills. The digital LCD display and PLC-based control ensure accuracy levels of up to +/- 0.2%, depending on the product, making it reliable for sensitive and high-value items.Q: What types of products can be packed using this weigh filler machine?

A: It is designed for versatile applications, including packaging granules, seeds, pulses, tea, spices, dry fruits, powders, and similar products. Its adjustable filling range (10 gm to 1000 gm) and customizable bag sizes enhance flexibility for various industries.Q: When is tool-less cleaning access beneficial in this machine?

A: Tool-less access enables quick and effortless cleaning of all contact parts, which is especially advantageous when frequently changing products or meeting strict hygiene standards in food and pharmaceutical production.Q: Where can the machine be installed and operated?

A: The machine operates efficiently in ambient temperatures up to 45C and is suited for manufacturing facilities in food, pharmaceutical, or chemical sectors. Its mobility, provided by heavy-duty caster wheels, allows placement and relocation within different areas of the production line.Q: What is the process for changing bag sizes or product types?

A: The machine offers fast changeover features. Bag size and filling range can be easily adjusted via the digital controls and PLC interface, with minimal intervention. Its user-friendly design streamlines the setup for new production runs.Q: How does the machine integrate with other packaging equipment?

A: This weigh filler can be seamlessly connected to conveyors, sealing, and coding systems, supporting both vertical and horizontal sealing operations. Such integration optimizes the entire packaging workflow and boosts overall productivity.Q: What are the key benefits of using this Semi Pneumatic Four Head Weigh Filler Machine?

A: Key benefits include precise filling, easy cleaning, robust stainless steel construction, customizable options for bag size and filling speed, high efficiency (up to 1800 packs per hour), and enhanced safety through overload and jam protection. Its design meets the needs of modern food, pharma, and chemical packaging applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

Other Products in 'Packing Machines' category

|

E. C. MACHINES INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese