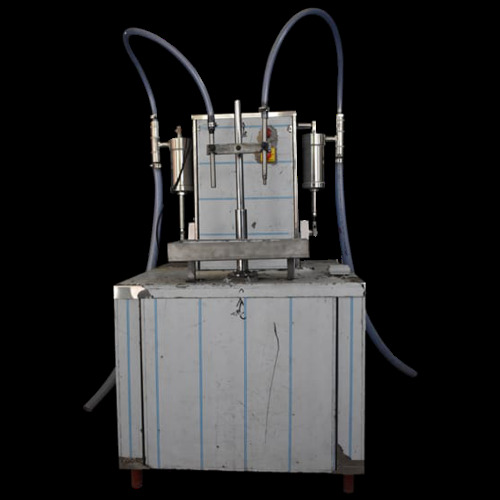

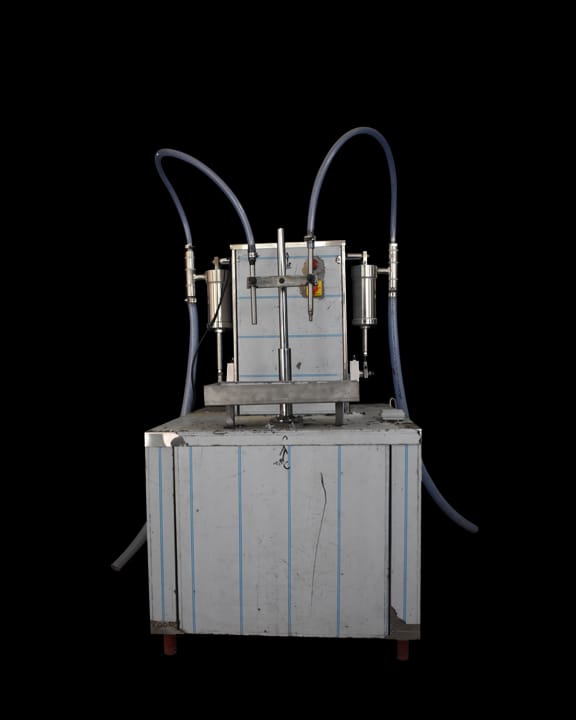

Semi Automatic Liquid Filler

135000.0 INR/Unit

Product Details:

- Product Type Semi Automatic Liquid Filler

- Material Stainless Steel

- Application Pharmaceutical, Chemical, Food, Cosmetic Industries

- Packaging Material Liquid Bottles, Jars

- Computerized No

- Automatic Grade Semi-Automatic

- Control System Manual or Pneumatic

- Click to View more

X

Semi Automatic Liquid Filler Price And Quantity

- 1 Unit

- 135000.0 INR/Unit

Semi Automatic Liquid Filler Product Specifications

- No

- Pharmaceutical, Chemical, Food, Cosmetic Industries

- Liquid Bottles, Jars

- 10-30 Bottles/Min

- Semi Automatic Liquid Filler

- Electric

- Stainless Steel

- Semi-Automatic

- 45 kg

- Silver

- Easy to Operate, High Accuracy, Low Maintenance

- Manual or Pneumatic

- 220 V/50 Hz

- 650 x 450 x 900 mm

Semi Automatic Liquid Filler Trade Information

- 10 Unit Per Month

- 3 Week

- Kerala, South India, Karnataka, Telangana, Tamil Nadu, Andhra Pradesh

Product Description

Semi Automatic Liquid Filler

We are engaged in offering large array of Liquid Filling Machine. We Manufacture product from best quality. Material & using latest techniques. Our product is highly demanded in the market for their reliability and effective filling. We offer technically advanced & quality tested liquid filling machine to our patrons.

Features:

- SS 304 Material to avoid rust free

- High Tensile Strength

- Sturdy Construction

- Electric Motor / Gear Box

- Peddle Switch / On & Off Switch

- Probability of in accuracy: + / -2%

Technical Details

| Filling Range | 1800bags/h |

| Automatic Grade | Semi-Automatic |

| Driven Type | Electric |

| Voltage | 220v/380v |

| Power | 1.2k |

Precision and Flexibility for Diverse Applications

This liquid filling machine is engineered to accommodate liquids with low to medium viscosity, delivering adjustable fill volumes to suit various packaging needs. Its design is well-suited for bottling operations in pharmaceutical, food, chemical, and cosmetic sectors, providing both manual and pneumatic control options for operational flexibility.

Effortless Operation and Maintenance

Ease of use is a core advantage, as the Semi Automatic Liquid Filler can be operated either by foot pedal or set to automatic cycles for efficient batch processing. The stainless steel body and mirror polished finish support hygienic practices, while the simple components allow for minimal regular maintenance without specialized skills.

Optimized Convenience and Mobility

Equipped with a 25-litre hopper and mounted on castor wheels, the machine is easy to move and set up within any workspace. This mobility, combined with its moderate size and 45 kg weight, ensures integration into existing production lines or laboratories without significant space or structural adjustments.

FAQs of Semi Automatic Liquid Filler:

Q: How does the piston filling mechanism work in this semi automatic liquid filler?

A: The piston filling mechanism draws the liquid into a cylinder from the hopper, and then dispenses a precise volume into containers when activated. This ensures consistent and accurate filling, making it ideal for low to medium viscosity liquids.Q: What types of liquids can be filled using this machine?

A: This filler is suitable for a wide range of low to medium viscosity liquids used in pharmaceutical, chemical, food, and cosmetic products. Examples include syrups, oils, cleansers, lotions, and similar products.Q: When should I use the foot pedal operation versus the automatic cycle mode?

A: Foot pedal operation is optimal for smaller batch runs or when manual control is preferred, while the automatic cycle mode is best for continuous production to improve throughput and efficiency.Q: Where can this liquid filling machine be used?

A: The filler is designed for versatile use in pharmaceutical labs, food and beverage factories, cosmetic production units, and chemical processing facilities that require precise filling into bottles or jars.Q: What maintenance is required to keep this machine in optimum condition?

A: Routine cleaning of the stainless steel surfaces and nozzle, as well as periodic checking of seals and piston mechanisms, will maintain accuracy and hygiene. The mirror polish and robust construction help minimize maintenance frequency.Q: How does the drip-proof stainless steel nozzle benefit the filling process?

A: The drip-proof nozzle eliminates leakage and spillage, maintaining a clean workspace and reducing product waste during filling operations.Q: What are the key advantages of using this semi-automatic liquid filler?

A: Its major benefits include high fill accuracy (1%), variable volume adjustment, easy mobility, low energy consumption, straightforward operation, and suitability for a diverse range of industries.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

We are inviting local inquiries from Karnataka, Kerala, Andhra Pradesh, Tamil Nadu, Telangana, Borders of Orissa & Borders of Maharashtra.

|

E. C. MACHINES INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese