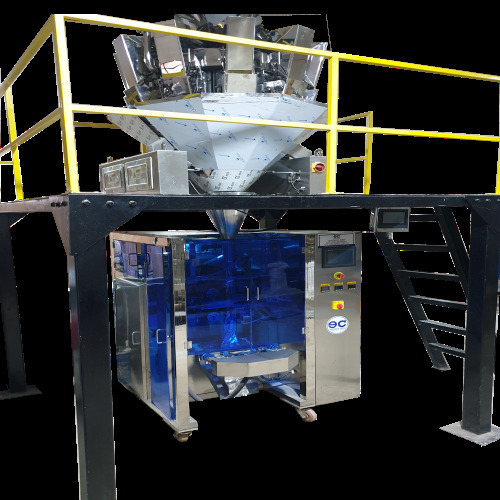

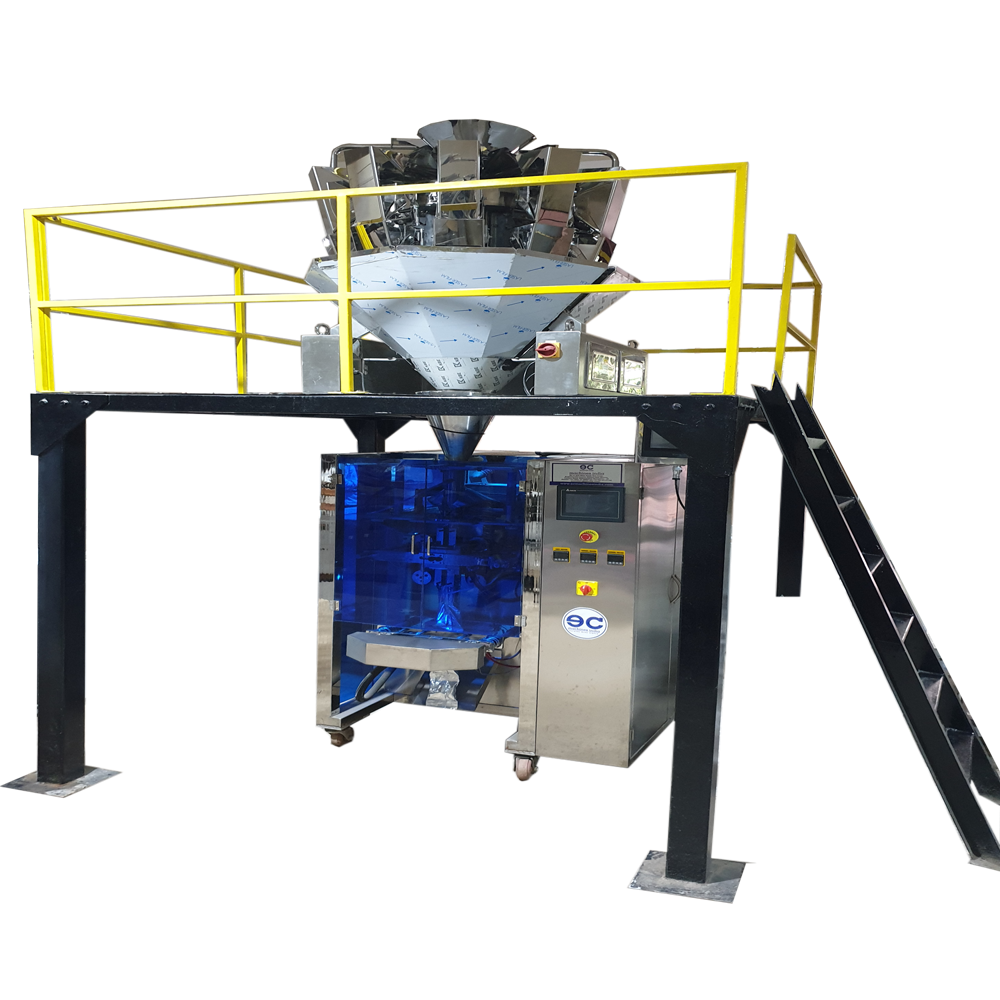

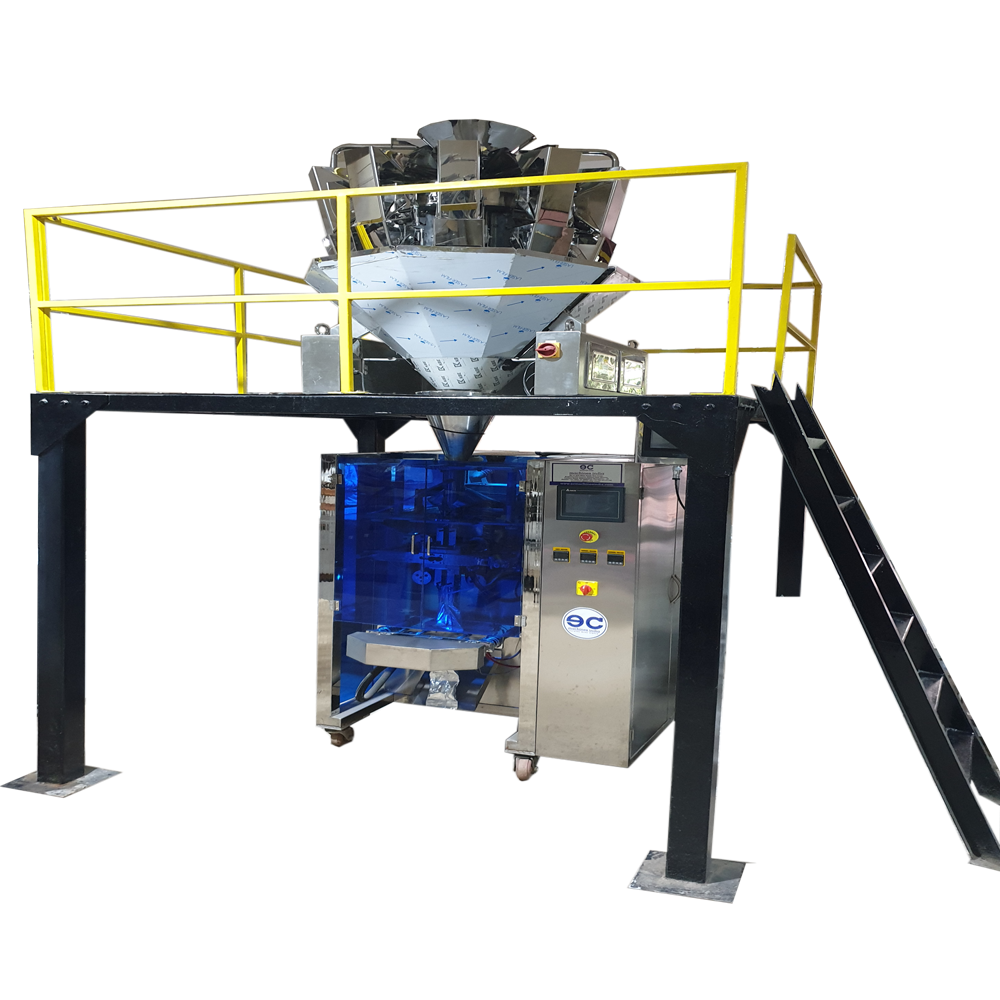

Automatic 14-Head Weigh Filler with Pneumatic Collar Type Bagger

1900000.0 INR/Unit

Product Details:

- Usage Industrial Packing

- Power Supply Single Phase/Three Phase

- Application Snacks, Granules, Pulses, Dry Fruits, Frozen Foods, Detergent, Pet Foods, etc.

- Noise Level 75 dB

- Filling Range 10 g to 1500 g (customizable)

- Features Modular Multihead Weighing, Pneumatic Film Pull, Vibratory Feeding, Auto Tare Correction, Fault Indication System

- Type Automatic 14-Head Weigh Filler with Pneumatic Collar Type Bagger

- Click to View more

X

Automatic 14-Head Weigh Filler with Pneumatic Collar Type Bagger Price And Quantity

- 1900000.0 INR/Unit

- 1 Unit

Automatic 14-Head Weigh Filler with Pneumatic Collar Type Bagger Product Specifications

- Snacks, Granules, Pulses, Dry Fruits, Frozen Foods, Detergent, Pet Foods, etc.

- Fully Automatic

- Modular Multihead Weighing, Pneumatic Film Pull, Vibratory Feeding, Auto Tare Correction, Fault Indication System

- 4.5 kW

- 1200 kg (approx.)

- 10 g to 1500 g (customizable)

- Single Phase/Three Phase

- Up to 80 packs/min (depending on product and pack size)

- 220-240V, 50 Hz

- Center Seal / Pillow Pack

- PLC-Based with Touch Screen HMI

- Stainless Steel (Food Grade SS304)

- Metallic Silver/Gray

- 75 dB

- High Accuracy, Fast Changeover, Low Maintenance

- Yes

- Electric + Pneumatic

- Collar Type Bagger

- Industrial Packing

- Automatic 14-Head Weigh Filler with Pneumatic Collar Type Bagger

- 2000 x 1500 x 3000 mm

Automatic 14-Head Weigh Filler with Pneumatic Collar Type Bagger Trade Information

- 10 Unit Per Month

- 5 Days

Product Description

The Automatic 10-Head Weigh Filler with Pneumatic Collar Type Bagger is a high-performance, precision packing machine designed for filling and bagging a variety of granular, powdered, or solid products. This advanced system combines accurate weighing, fast filling, and efficient sealing, making it ideal for industries such as food processing, chemicals, and pharmaceuticals.

Key Features:

- 10-Head Weighing System: Provides precise and consistent product measurement, reducing product wastage and ensuring accuracy.

- Pneumatic Collar Type Bagger: Uses pneumatic technology to form, fill, and seal bags efficiently, minimizing the risk of contamination and improving speed.

- High-Speed Operation: Capable of handling high volumes, significantly boosting production efficiency.

- Versatile Filling Range: Suitable for a variety of products, including grains, powders, and snacks.

- User-Friendly Interface: Easy-to-operate control system for quick adjustments and real-time monitoring.

- Durable Construction: Built with high-quality materials to withstand the demands of continuous operation.

Benefits:

- Accuracy and Consistency: Guarantees precise filling and consistent product weight, leading to reduced waste and improved quality control.

- Increased Productivity: With high-speed performance, it meets large-scale production requirements with ease.

- Enhanced Sealing: The pneumatic collar ensures strong, secure, and reliable bag seals, preventing product leakage or contamination.

- Flexible Applications: Ideal for packaging various types of products, including food, grains, chemicals, pet food, and more.

This machine is an excellent solution for manufacturers seeking to enhance packing efficiency, improve accuracy, and reduce labor costs while maintaining product quality.

Unmatched Packaging Precision and Efficiency

The 14-head weigh filler is engineered for high accuracy and speed, delivering consistent pack weights from 10 g to 1500 g. Its advanced modular multihead weighing and vibratory feeding mechanisms ensure reliability, minimal product giveaway, and rapid changeovers between product types, making it perfect for diverse production lines.

User-Friendly Multi-Language Operation

Featuring an intuitive 7-inch color touch HMI and multi-language support, operators can easily configure and monitor the machine. Recipe memory storage simplifies the packaging process for multiple products, while real-time alarms and automatic error displays facilitate prompt troubleshooting and maintenance.

Robust Build and Safety Standards

Constructed entirely of food-grade SS304 stainless steel, every product-contact part upholds strict hygiene standards. Interlocked safety covers, emergency stop features, and noise levels below 75 dB ensure a safe and comfortable working environment. The PLC-based control system further enhances operational security and accuracy.

FAQs of Automatic 14-Head Weigh Filler with Pneumatic Collar Type Bagger:

Q: How does the 14-head weigh filler with pneumatic collar type bagger work?

A: This automatic machine uses 14 independent weighing heads for precise measurement of products, which are then dispensed into bags formed and sealed by a pneumatic collar type bagger. The entire process is PLC-controlled and monitored via a 7-inch touchscreen, ensuring accuracy and speed with minimal intervention.Q: What types of products and packaging materials can this machine handle?

A: The machine is suitable for a wide range of products like snacks, pulses, granules, dry fruits, frozen foods, detergents, and pet foods. It supports various films including laminated, BOPP, PET, and PE, accommodating bag widths from 80 mm to 250 mm and lengths from 100 mm to 400 mm.Q: Where is this machine typically used?

A: This weigh filler and bagger is ideal for industrial packing operationssuch as in food processing, pet food, detergent manufacturing, and similar industrieswhere high throughput, accuracy, and hygiene are essential.Q: What is the process for changing products or pack sizes?

A: The system features modular construction and recipe memory, enabling quick and easy changeovers. Operators can adjust pack sizes, products, and sealing types directly through the HMI with minimal downtime, optimizing workflow efficiency.Q: What are the main benefits of using this packaging machine?

A: Key benefits include consistent weighing accuracy, high pack speed (up to 80 packs/min), hygienic construction, simplified operation through multi-language HMI, recipe memory for frequently packed products, robust safety mechanisms, and reduced maintenance requirements.Q: How do the safety features enhance operator protection?

A: Safety is prioritized with interlocked covers that prevent access during operation, an emergency stop mechanism for instant halting, automatic fault and alarm indication, and a low-noise design, collectively fostering a secure and user-friendly environment.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Packing Machines' category

We are inviting local inquiries from Karnataka, Kerala, Andhra Pradesh, Tamil Nadu, Telangana, Borders of Orissa & Borders of Maharashtra.

|

E. C. MACHINES INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese