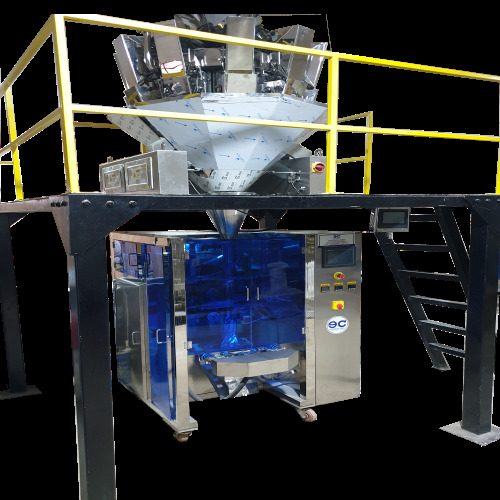

Collar Type with Four Head Weigh Filler Machine

Product Details:

- Application Granules, Dry Fruits, Pulses, Snacks, Seeds, Sugar, Tea, etc.

- Usage Industrial Packaging

- Noise Level Low

- Filling Range 10 gm to 1 kg (Adjustable)

- Power Supply Single Phase / Three Phase

- Features Touch Screen Operation, Stainless Steel Contact Parts, High Output, Batch Coding Attachment (Optional)

- Type Collar Type with Four Head Weigh Filler Machine

- Click to View more

Collar Type with Four Head Weigh Filler Machine Price And Quantity

- 1 Unit

Collar Type with Four Head Weigh Filler Machine Product Specifications

- 1800 mm x 1200 mm x 2300 mm (Approx.)

- Yes

- Granules, Dry Fruits, Pulses, Snacks, Seeds, Sugar, Tea, etc.

- Collar Type with Four Head Weigh Filler Machine

- Center Sealing

- 600-750 kg (Approx.)

- Industrial Packaging

- Single Phase / Three Phase

- Approx. 3 kW

- PLC Based

- 220-240V, 50Hz

- Electric

- Silver & Blue (as per image)

- Touch Screen Operation, Stainless Steel Contact Parts, High Output, Batch Coding Attachment (Optional)

- 30-60 Pouches/min (Depending on Product)

- Automatic

- High Accuracy Weighing, User-Friendly Interface

- 10 gm to 1 kg (Adjustable)

- Stainless Steel

- Automatic Weigh Filler

- Low

Collar Type with Four Head Weigh Filler Machine Trade Information

- Per Month

- Week

- Kerala, South India, Telangana, Andhra Pradesh, Tamil Nadu, Karnataka

Product Description

Collar type with Four Head Weigh Filler Machine

TECHNICAL SPECIFICATIONS

| Product application | Collar Type for Four Head Weigh Filler |

| Sealing Type | Centre Seal / Three Side Seal |

| Packing Speed | 20 to 30 pouches / min |

| Packaging Film | Laminated Film |

| Filling System | Weighing System |

| Maximum roll width | 450mm |

| Maximum roll dia | 350mm |

| Maximum Pouch length | 300mm |

| Hopper Capacity | 40 Kg |

| PLC | Deltas |

| AC Drive | Telemanique / Delta |

| Micro View | Touch screen Delta |

| Temperature Controller | PID based |

| Photo Cell | Colour Sensor |

| Feeding of main hopper | Through infeed Screw Conveyor (Optional) |

| Product contact parts | SS-304 |

| Water Chiller | Required for cooling sealing (Optional) and End Pouch Conveyor |

| Compressed air required | 9cfm @ 9kg / sq |

| Power require | 4 KW |

| Machine Dimension | 6 FT X 4 FT X 12 FT (L x W x H) |

| Weight | 1150 Kg |

| Application | Semi Pneumatic with Weigh Filler to pack Whole Spices/ Pulses/ Rice/ Dry Fruits Masala Peanut / Batani/ Mixture / Rice / Tutti Frutti |

| Optional attachment (At on Extra Cost) | Electronic Batch Coding Device / Hot Ribbon Coding System / Solid Ink Roller Coding System / Nitrogen Flushing |

High-Precision Weighing System

Equipped with four highly accurate filling heads, this machine ensures consistent weight measurement for each pouch, resulting in minimal wastage and improved product quality. The system supports granular and free-flowing items, adjusting to product variations effortlessly.

Adaptable Package Dimensions

Bag length and width are fully adjustable, catering to package requirements ranging from 50300 mm in length and 80200 mm in width. This flexibility enhances your operations ability to handle diverse product lines without needing multiple machines.

Reliable Construction and Safety

Featuring a heavy-duty, rustproof, modular stainless steel frame, the machine upholds long-term durability. Food-grade SS304/316 contact parts guarantee hygiene, while built-in safety features like overload protection and emergency stop prioritize operator security.

User-Friendly Operation

A PLC-based control system and large LCD/touch screen provide intuitive, multilingual operation. Batch coding, automatic settings, and alert systems ensure smooth functioning and traceable production, making the machine exceptionally user-friendly.

FAQs of Collar Type with Four Head Weigh Filler Machine:

Q: How does the four head weigh filler machine work?

A: The machine utilizes four independent weigh filling heads to simultaneously measure and dispense accurate quantities of granular or free-flowing products into pouches. Product is fed into hoppers, weighed, and automatically filled, followed by sealing and batch coding (if enabled).Q: What types of packaging materials are compatible with this machine?

A: This machine supports a variety of packaging materials, including laminated films, PET/Poly, and metallized films, accommodating industrial requirements for product protection and shelf life.Q: When should I adjust the bag length and width?

A: You should adjust the bag dimensions when switching between products or packaging sizes. The machine allows bag lengths between 50300 mm and widths from 80200 mm, suitable for a range of applications in the food and packaging industries.Q: Where can this machine be installed and used?

A: It is engineered for industrial usage and can be installed in factories, packaging units, or food processing facilities with adequate power and pneumatic supply, and where environmental temperatures range from 5C to 50C.Q: What is the process involved from feeding to finished pouch?

A: Product is loaded into the hopper, weighed by the four filling heads, dispensed into film-formed pouches, sealed (center sealing), optionally batch-coded, and ejectedready for boxing or shipment.Q: How does the machine enhance packaging efficiency?

A: With a capacity of 3060 pouches per minute, computerized accuracy, and automatic fault alerts, the machine boosts throughput, minimizes errors, and reduces manpower, resulting in consistent and efficient packaging.Q: What are the key benefits of using this packaging machine?

A: Key advantages include high fill accuracy, flexibility for different product and bag sizes, fast operational speed, food safety compliance, and a user-friendly interface with robust safety mechanisms. This combination ensures reliable, cost-effective packaging for diverse applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

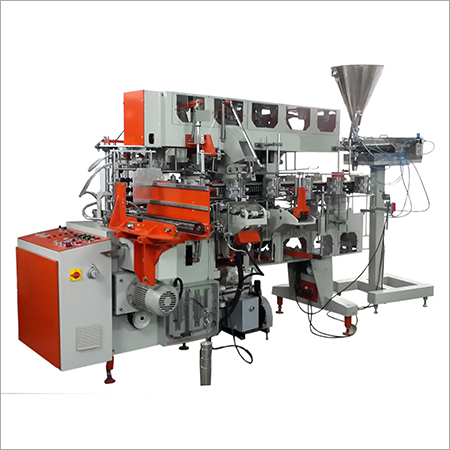

Other Products in 'Packing Machines' category

|

E. C. MACHINES INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese