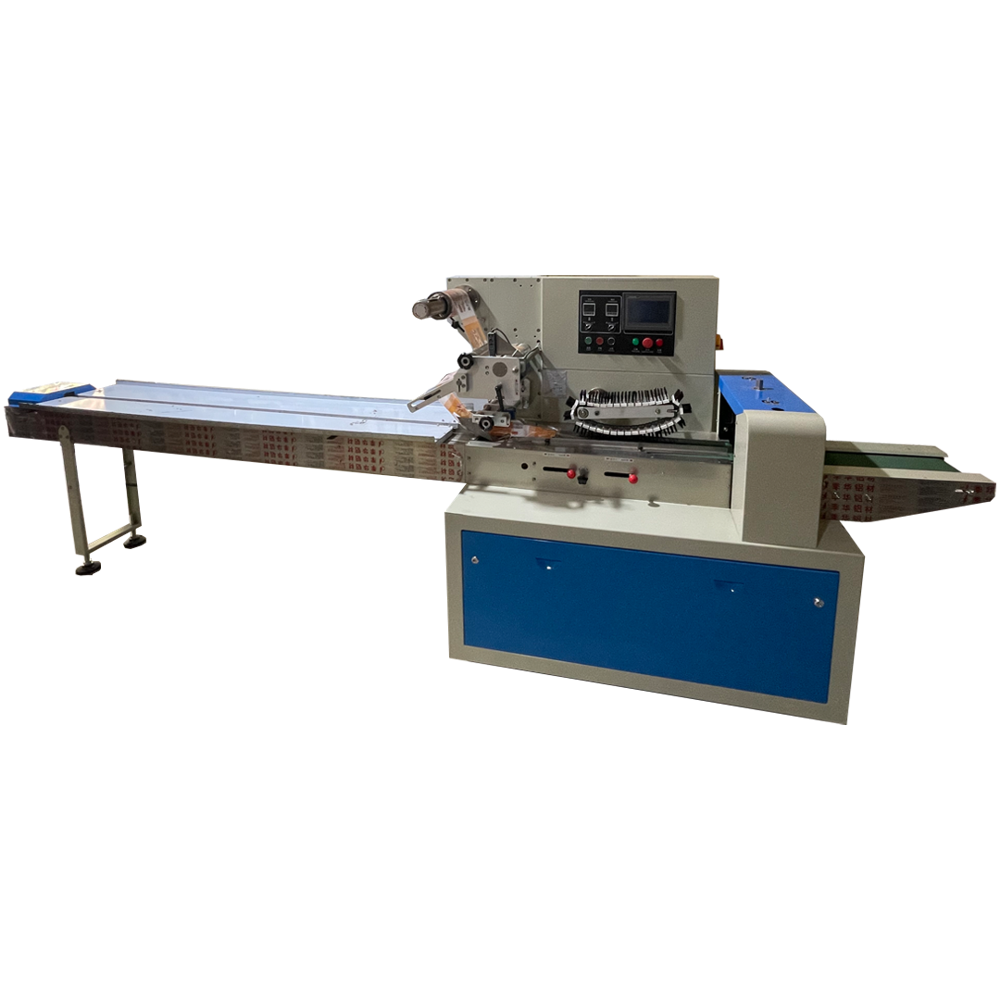

Automatic Horizontal Flow Wrap Machine 3 servo

450000.0 INR/Unit

Product Details:

- Type Automatic Horizontal Flow Wrap Machine (3 Servo)

- Material Stainless Steel

- Capacity 60-350 packs per minute

- Computerized Yes

- Automatic Grade Automatic

- Control System PLC with Touch Screen Interface

- Shrink Speed Up to 350 ppm

- Click to View more

X

Automatic Horizontal Flow Wrap Machine 3 servo Price And Quantity

- 450000.0 INR/Unit

- 1 Unit

Automatic Horizontal Flow Wrap Machine 3 servo Product Specifications

- Metallic Silver

- Automatic Horizontal Flow Wrap Machine (3 Servo)

- Up to 350 ppm

- 0.6 Mpa

- Max 350 mm

- 60-350 packs per minute

- Stainless Steel

- 220V/380V, 50Hz/60Hz

- PLC with Touch Screen Interface

- Automatic

- Yes

- 4200mm x 1100mm x 1600mm

- 800 kg

Automatic Horizontal Flow Wrap Machine 3 servo Trade Information

- 20 Unit Per Month

- 2-3 Week

- Karnataka, Kerala, Andhra Pradesh, Tamil Nadu, Telangana, South India

Product Description

We are a prominent manufacturer and supplier of a wide ambit of Automatic Horizontal Flow Wrap Machine. Our scope of machine is composed and grew as per the worldwide quality guidelines. This adaptable Automatic Horizontal Flow Wrap Machine is preferably utilized for wrapping cubical, unpredictable molded strong items and tube shaped items, for example, dispensable syringe, jug, cleanser, cake and prefilled pockets. Our ambit of Automatic Horizontal Flow Wrap Machine is best viewed for highlights, for example, vitality productive, less support, smooth working, spares time and vitality etc.

Efficient and Flexible Packaging

This flow wrap machine enables rapid packaging with a maximum speed of 350 packs per minute and adjustable pack lengths. Its three-servo motor design ensures precise control, enhanced synchronization, and consistent seal quality, accommodating various product sizes and pack styles.

User-Friendly Operation and Safety

The multi-language touch screen interface simplifies operation, allowing users to adjust settings and monitor productions seamlessly. Advanced safety features, including emergency stop buttons and sensors, protect operators and prevent potential accidents, ensuring safe daily use.

Versatile Application Across Industries

Engineered for heat-sealable materials like BOPP and laminated films, the machine suits diverse sectors such as food, pharmaceuticals, and non-food packaging. Its sturdy stainless steel construction and low noise levels (<70 dB) make it suitable for industrial environments demanding hygiene and quiet operation.

FAQs of Automatic Horizontal Flow Wrap Machine 3 servo:

Q: How does the 3-servo system enhance the performance of this automatic flow wrap machine?

A: The 3-servo system allows for highly accurate control over the feeding, sealing, and cutting processes. This increases packaging speed, ensures consistent quality in every pack, and offers flexibility for different product sizes, resulting in optimal performance and efficient operation.Q: What types of films and products can be packaged using this machine?

A: The machine is compatible with heat-sealable films such as BOPP and laminated films, supporting a maximum film width of 400 mm. It can handle various products up to 80 mm in height, making it versatile for food, pharmaceuticals, and other non-food items.Q: When is the date coding device required, and how is it integrated?

A: The date coding device is optional and can be requested based on your packaging needs. If required, it is seamlessly integrated into the machine, allowing you to automatically print batch details, expiry dates, and other codes during the packing process.Q: Where is this flow wrap machine most effectively used?

A: This machine is ideal for use in manufacturing facilities, food processing plants, pharmaceutical production lines, and other packaging environments where efficiency, hygiene, and automation are priorities.Q: What is the process for adjusting pack length and changing film rolls?

A: Changing the pack length is straightforward through the touch screen interface, allowing quick adjustments within the 80-400 mm range. For film rolls, the machine supports a maximum diameter of 350 mm, and the stainless steel design enables easy roll change while maintaining optimal hygiene.Q: How does the machine benefit daily operations and long-term maintenance needs?

A: The automatic grade, PLC touch screen controls, and safety features streamline daily packaging tasks, reducing manual interventions. Its low-maintenance design, coupled with durable stainless steel construction, ensures long-term reliability and straightforward servicing.Q: What safety measures are implemented for operator protection?

A: The machine is equipped with an emergency stop button and multiple safety sensors. These features promptly halt operations if any anomalies or unsafe conditions are detected, ensuring a secure working environment for operators.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Other Products in 'Wrapping Machine' category

We are inviting local inquiries from Karnataka, Kerala, Andhra Pradesh, Tamil Nadu, Telangana, Borders of Orissa & Borders of Maharashtra.

|

E. C. MACHINES INDIA

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese